Manufacturers today operate in a fast-paced, competitive world marked by disruptive technology and increasingly complicated supply chains, which present both difficulties, as well as opportunities. Process improvement activities can now be implemented rapidly through the right use of process intelligence tools while yielding results immediately. Companies who do so, can view the bigger picture while understanding the importance and necessity for constant improvement in ongoing processes that can accommodate dynamic market conditions.

In simple terms, supply chain management refers to the process that begins with the procurement of raw materials and ends in the production of finalized goods and services.

The administration of the movement of goods and services is referred to as supply chain management, and it encompasses all procedures that aim to transform or convert raw materials into finished items. It entails a company’s supply side activities being actively streamlined in order to optimize customer value and obtain a competitive advantage in the marketplace.

Demand management, supply management, sales & operations planning, and Product portfolio management are the 4 essential elements of Supply Chain Management, and include :

Typically, supply chain management aims to centralize or link a product’s manufacturing, shipment, and distribution. Companies can reduce extra expenses and deliver items to customers faster by optimizing the supply chain. Internal inventories, internal manufacturing, distribution, sales, and company vendor inventories are all under tighter supervision.

Process Intelligence is the systematic collection of data that is analyzed to better processes, magnify inefficiencies/ delays and augment operational workflow. Process intelligence’s purpose is to give an organization reliable information about where bottlenecks lie in the process, what tasks are involved, who is accountable for these respective tasks, and the time taken on an average to complete the set tasks.

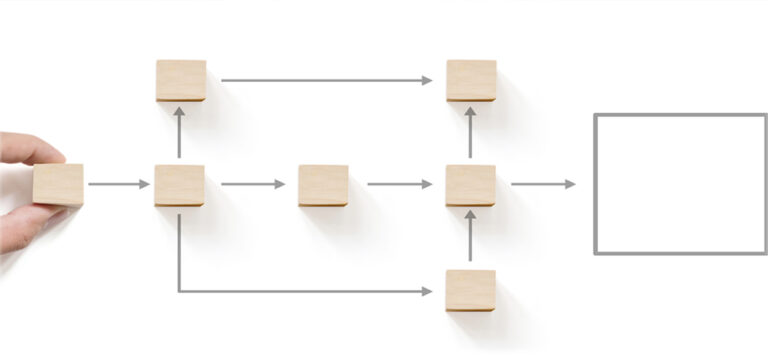

Supply chain managers can make use of Process intelligence tools to improve process management through monitoring and analysis of processes on a regular basis while being able to gain a 360 degree review of the entire process flow in real -time. This can help track every transaction in the supply chain that is capable of having a detrimental impact on process performance, product quality and customer satisfaction.

Supply chain management solutions are used by a great majority of businesses. Existing systems like Enterprise resource planning(ERP) and Advanced planning & scheduling(APS) limit the magnitude of insights that one can derive from end-to-end processes due to their independent nature which invariably deters performance. Many gaps and inefficiencies that were previously addressed with a manual effort prone to human mistake are still present in the process, which Process Intelligence software tools can help discover!

Processes are getting more difficult to monitor and optimize as supply networks become more global and complicated. Without a thorough perspective of operational procedures, identifying the core cause of inefficiencies can be difficult.

Process intelligence tools improve the order-to-cash process by delivering a thorough visual map of all organizational operations across several back-end systems, departments, teams, and locations. Supply chain leaders may use these modern tools to quickly identify bottlenecks, optimize operations, track vendor performance, and increase profit margins.

Models can become vast and sometimes unmanageable as supply chain planning often comprises a plethora of suppliers, customers, channels and pricing schemes—particularly when spreadsheets are used as the planning tool. Incorporating a real-time data solution enables for extremely precise planning and lowers the danger of stock-outs or excess inventory.

Supply chain managers can also improve and enhance profit margins by reducing considerable time in processes like procure-to-pay or invoice processing, wherein, cost saving benefits can be successfully attained.

It’s simple to see which vendors are the most timely, dependable, and responsive when you have a thorough view of your operations. By monitoring and recognizing the following characteristics, process intelligence allows you to precisely measure and track vendor performance:

Not only does comprehensive process intelligence successfully monitor the complete scope of organizational processes, but it also analyses the direct cost associated with each process, allowing firms to deliberately improve the cost of completing each process.

Therefore, Process intelligence solutions can help firms thrive in their digital transformation efforts by making their supply chains more productive, coherent, and ultimately successful.

Supply chain management may use process intelligence to decrease costs more strategically, identify the best vendor partners, improve capacity planning, and streamline workflows, all of which are instrumental to customer loyalty & customer satisfaction.

With Re-vive, you gather deep insights into what your operational data says, making inefficiencies and bottlenecks distinctly visible and easier to tackle.

Copyright © 2024 By Re-vive. All rights reserved.